Top-Quality Carbon Steel Products by Leading Carbon Steel Manufacturers

Discover top-quality high carbon steel products from Shunbei Ronghang. High strength, diverse applications, and exceptional durability.

Introduction to Shunbei Ronghang - Trusted Carbon Steel Suppliers

Foshan Shunbei Ronghang Metal Manufacturing Co., Ltd is a leading name in the high-carbon steel manufacturing industry, renowned for its expertise and reliability. With a rich history and a commitment to quality, we provide top-grade carbon steel products tailored to meet the stringent demands of various industrial applications. Our extensive range of carbon steel grades ensures that you find the perfect material for your specific needs, whether it’s for manufacturing, construction, or specialized engineering projects.

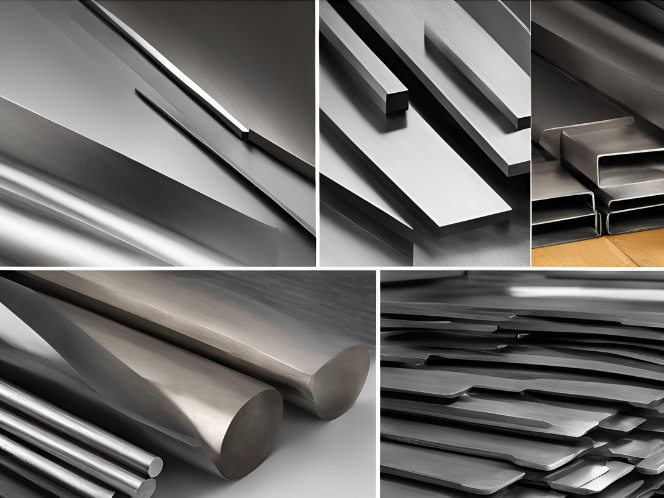

Our High Carbon Steel Products

Explore our extensive range of high carbon steel products, including high carbon steel plates, bars, tubes, and wires. Each product page features high-resolution images, detailed descriptions, specifications, performance characteristics, user reviews, and application cases. Our high carbon steel offerings are ideal for various industries, ensuring superior strength and durability. Discover the perfect solution for your needs with our certified, high-quality materials.

Product Specifications

Shunbei Ronghang offers comprehensive specifications for each high-carbon steel product, ensuring detailed performance characteristics to build customer trust.

| Property | A36 Mild Steel (ASTM A36) | 1018 Mild Steel (1018) | 1144 Stressproof-equivalent Steel |

|---|---|---|---|

| Ultimate Tensile Strength, psi | 58,000 - 79,800 | 63,800 | 100,000 |

| Yield Strength, psi | 36,300 | 53,700 | 90,000 |

| Elongation | 20.0% | 15.0% | 10.0% |

| Rockwell Hardness | B71 | B71 | C30 |

| Iron (Fe) | 99% | 98.81 - 99.26% | 98.0% |

| Carbon (C) | 0.26% | 0.18% | 0.40% |

| Manganese (Mn) | 0.75% | 0.6 - 0.9% | 1.35% |

| Copper (Cu) | 0.2% | - | - |

| Phosphorus (P) | 0.04% max | 0.04% max | 0.04% max |

| Sulfur (S) | 0.05% max | 0.05% max | 0.24% |

| Thermal Properties | Metric | English | Comments |

|---|---|---|---|

| CTE, linear | 12.1 µm/m-℃ | 6.72 µin/in-°F | @Temperature 0.000 / 100 ℃ |

| Specific Heat Capacity | 0.486 J/g-°C | 0.116 BTU/lb-°F | @Temperature >=100 ℃ |

| Thermal Conductivity | 51.9 W/m-K | 360 BTU-in/hr-ft2-ºF | - |

| Electrical Properties | Metric | English | Comments |

|---|---|---|---|

| Electrical Resistivity | 0.0000169 ohm-cm | 0.0000169 ohm-cm | - |

| Mechanical Properties | Metric | English | Comments |

|---|---|---|---|

| Modulus of Elasticity | 205 GPa | 29700 ksi | Typical for steel |

| Bulk Modulus | 160 GPa | 23200 ksi | Typical for steel |

| Poisson's Ratio | 0.29 | 0.29 | Typical for steel |

| Shear Modulus | 80.0 GPa | 11600 ksi | Typical for steel |

| Machinability | 75.00% | 75.00% | Based on AISI 1212 steel as 100% |

| Physical Properties | Standard | Metric |

|---|---|---|

| Density at room temperature | 0.2833 lb/in.3 | 7.85 x 10^3 kg/m3 |

| Specific gravity at room temperature | 7.85 | 7.85 |

| Shear modulus at room temperature | 10.88-11.61 ksi x 10^3 | 75.0-80.0 GPa |

| Melting point | 2597ºF | 1425°C |

| Poisson's Ratio at room temperature | 0.29 | 0.29 |

High Carbon Steel Properties

Discover the exceptional properties of high carbon steel, including its hardness, strength, machinability, and corrosion resistance, tailored for various industrial applications.

Superior Hardness and Strength

High carbon steel grades like W1 and O1 offer maximum Rockwell hardness up to C62, providing excellent wear resistance and durability for demanding applications.

Excellent Machinability

Grades such as 12L14 and 1144 are designed for superior machinability, making them ideal for precision components with minimal deformation and high-quality surface finishes.

Outstanding Corrosion Resistance

High carbon steels like D2 and A2 are engineered with high chromium content, ensuring excellent corrosion and wear resistance, perfect for harsh environments.

Versatile Heat Treatment

Grades such as M2 and S7 maintain their properties even after heat treatment, offering stability and minimal decarburization, essential for high-speed cutting tools and shock-resistant applications.

Applications of High Carbon Steel

Construction Engineering

High carbon steel is a cornerstone in construction engineering, providing the necessary strength and durability for structural components. Its high tensile strength makes it ideal for reinforcing bars, beams, and columns in skyscrapers and bridges. The material's wear resistance ensures longevity and reliability, even under heavy loads and harsh environmental conditions. Explore how high carbon steel enhances the safety and stability of modern infrastructure.

Automotive Manufacturing

In the automotive industry, high carbon steel is essential for manufacturing critical components such as springs, gears, and cutting tools. Its superior hardness and strength ensure that these parts can withstand high stress and wear, contributing to vehicle safety and performance. The material's ability to be heat-treated further enhances its mechanical properties, making it a preferred choice for high-performance automotive applications.

Mechanical Engineering

Mechanical engineering relies heavily on high carbon steel for the production of machinery components such as gears, crankshafts, and cutting tools. The material's exceptional hardness and wear resistance make it suitable for high-stress applications, ensuring the longevity and efficiency of mechanical systems. High carbon steel's versatility in being hardened and tempered allows engineers to tailor its properties to specific requirements, enhancing overall machine performance.

Pipeline Transportation

High carbon steel is a preferred material for pipeline transportation due to its strength and durability. It is used in the construction of pipelines that transport oil, gas, and other fluids, where resistance to wear and pressure is crucial. The material's ability to withstand harsh environmental conditions and high pressures ensures the safe and efficient transport of resources over long distances. Learn how high carbon steel contributes to the reliability of pipeline infrastructure.

Our Services

High-Quality Assurance

We implement rigorous quality assurance protocols to ensure every product meets the highest standards. Our QA and QC teams utilize advanced statistical process control (SPC) methods to monitor and improve product quality continuously.

Customized Services

Tailor-made solutions are our specialty. We offer customized services to meet your specific requirements, from unique product designs to specialized manufacturing processes, ensuring your exact needs are met.

Rapid Delivery

Time is of the essence, and we guarantee fast and reliable delivery. Our streamlined processes and efficient logistics ensure that your orders are delivered promptly, minimizing downtime and maximizing productivity.

Technical Support

Our expert technical support team is always ready to assist you. Whether you need help with product selection, troubleshooting, or optimizing your processes, we provide the guidance and support you need to succeed.

Advanced Testing Methods

We employ advanced testing methods such as Rockwell hardness tests, salt fog tests, and impact tests to ensure the durability and reliability of our products. Our state-of-the-art testing facilities guarantee that every product meets stringent quality standards.

In-Process Inspection

Our in-process inspection approach ensures quality at every production stage. Utilizing automatic sensors and manual spot-checks, we maintain high standards and prevent defects before they occur.

Precision Machining

Precision is key in our machining processes. We use cutting-edge technology and meticulous measurement techniques to achieve exacting standards, ensuring every component fits perfectly and performs flawlessly.

Nondestructive Testing

Our nondestructive testing methods, including magnetic-particle inspection and ultrasonic testing, ensure the integrity of materials without compromising their usability. This guarantees the highest quality while preserving the product's functionality.

Why Choose Us - Leading Carbon Steel Suppliers Comparison

Discover why Shunbei Ronghang stands out among leading carbon steel suppliers. By comparing our offerings with competitors, we highlight our unique strengths and advantages, ensuring you make an informed choice.

Superior Material Grades: Shunbei Ronghang vs. Competitors

Shunbei Ronghang offers a comprehensive range of carbon steel grades, from low to very high carbon content, catering to diverse industrial needs. Our low carbon steel, with 0.05%-0.25% carbon, is cost-effective and easy to shape, ideal for applications requiring malleability. In contrast, competitors often limit their offerings to fewer grades, restricting versatility. Our medium carbon steel (0.29%-0.54% carbon) balances ductility and strength, suitable for long-wearing applications. High carbon steel (0.55%-0.95% carbon) and very high carbon steel (0.96%-2.1% carbon) provide exceptional strength and shape memory, perfect for springs and wires. Competitors may not match this range, often lacking the higher carbon options that offer superior performance in demanding applications.

Cost-Effectiveness: Shunbei Ronghang vs. Competitors

Shunbei Ronghang provides cost-effective solutions without compromising quality. Our ASTM A36 mild steel, a hot-rolled option, is significantly more affordable than many competitors' offerings. Despite its lower yield strength compared to 1018 steel, it remains a popular choice due to its cost efficiency and availability in various shapes like I-Beams and H-beams. Competitors often offer similar materials at higher prices, limiting budget-friendly options. Additionally, our 1018 mild steel, a cold-rolled variant, offers a superior surface finish and better properties at a competitive price point. This balance of quality and affordability sets us apart, ensuring you receive the best value for your investment.

Machinability and Performance: Shunbei Ronghang vs. Competitors

At Shunbei Ronghang, we prioritize machinability and performance. Our 1144 (Stressproof-equivalent) steel stands out with its high strength and improved ductility, offering low distortion or warpage post-machining. This makes it an excellent choice for precision applications. Competitors often lack such specialized materials, leading to higher distortion rates and reduced machining efficiency. Our 1018 mild steel, with a machinability rating of 83% of AISI 1212 steel, ensures ease of machining, outperforming many competitor materials. This focus on machinability and performance ensures that our steel products meet the highest standards, providing reliable and efficient solutions for your projects.

Customer Success Stories

Discover how Shunbei Ronghang innovative solutions have transformed various industries. Our detailed case studies showcase the effectiveness of our products, from washers to keystock, through high-quality images and comprehensive descriptions.

Precision in Railway Components with Medium Carbon Steel

Shunbei Ronghang medium carbon steel, specifically AISI/SAE 1040, has been instrumental in manufacturing high-strength railway components. Our steel undergoes a rigorous process of austenitizing, quenching, and tempering to enhance its mechanical properties. This treatment ensures the steel's durability and reliability, making it ideal for critical applications such as railway wheels and tracks. The enhanced strength and low hardenability of our medium carbon steel provide the necessary resilience to withstand the demanding conditions of railway operations. This case highlights the significant improvements in performance and longevity of railway components, thanks to our advanced steel processing techniques.

High Carbon Steel for Cutting Tools and Blades

Our high carbon steel, with carbon contents ranging from 0.55% to 1.4%, is renowned for its hardness and strength. This steel is particularly suited for manufacturing cutting tools and blades, which require exceptional wear resistance.Shunbei Ronghang high carbon steel undergoes a meticulous hardening and tempering process, resulting in tools that maintain sharpness and durability even under intense use. This case study demonstrates the superior performance of our high carbon steel in producing reliable and long-lasting cutting tools, essential for various industrial applications.

Cold Finished Steel for Keystock Manufacturing

Shunbei Ronghang cold finished steel is a cornerstone in the production of high-quality keystock. The cold finishing process involves running hot rolled, pickled, and oiled steel through a series of progressive dies or rollers at room temperature. This process enhances the steel's hardness, strength, and finish, making it ideal for keystock applications. Additionally, our keystock undergoes bead blasting to achieve a bright, flawless surface, ensuring seamless insertion into keyways. This case highlights the precision and quality of our cold finished steel in delivering superior keystock products.

Innovative Stamping Solutions for Custom Washers

Shunbei Ronghang expertise in stamping has revolutionized the production of custom washers. Utilizing advanced tooling and processes, we achieve near-universal low-cost setups for orders of 10,000 pieces or less. Our stamping operations ensure precise and consistent impressions in metal, tailored to meet specific customer requirements. This case study showcases the efficiency and cost-effectiveness of our stamping solutions, providing high-quality custom washers that meet the stringent demands of various industrial applications.

Contact Us

Have questions or need a quote? Our team is here to assist you with any inquiries regarding our services and products. Fill out the form below or contact us directly to get the information you need.