Phone / WhatsApp:

+86-13288385958

E-mail: sale20@shunbeifactory.com

E-mail: sale20@shunbeifactory.com

Xingye 9th Road, Guanglong Industrial Zone, Yongxing village, Chencun Town, Shunde District, Foshan City, Guangdong, China

DT4A/DT4E/DT4C

10mm-12000mm

ASTM ASME SUS JIS DIN

130mm-1000mm (optional)

ROD

30% TT in advance, 70% TT /70% LC at sight balance before shipment

support

FOB, EXW, CIF, CFR

10 TON

Electronics and electrical engineering, electrical components, magnetic materials, amorphous products, relays

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

| DT4E pure iron is an iron alloy with a carbon content of less than 0.02%, also known as wrought iron. It belongs to the category of electromagnetic pure iron products. According to the different levels of magnetic properties, it can be divided into general grade, advanced grade, special grade and super grade, among which DT4E belongs to special grade pure iron. DT4E pure iron is mainly used in the manufacture of electronic and electrical, electrical components, magnetic materials, amorphous products, relays and other products. It has excellent magnetic properties and stable magnetic performance, which can meet the needs of various application fields. | |||||||||

Product Details

|

Product Description

| Name | low Carbon Steel Round Bar |

| OD | 10 to 400mm( according to customer's special request) |

| Length | 1m to 12m(according to customer's special request) |

| Surface | Mild steel plain finish, hot dip galvanized, color coated, ect. |

| Materials | Carbon steel |

| MOQ | 5 TON.We also can accept sample order. |

| Technology | Hot roll, cold roll, cold drawn |

| Quality | Approved by SGS,ISO |

|

Pure Iron Chemical composition analysis(%)

DT4C pure iron has excellent chemical purity, very low carbon content (0.0015-0.0016%), and low sulfur and silicon content, ensuring stable performance in electromagnetic applications. Its superior magnetic properties include low coercivity (≤32 A/m) and high magnetic permeability (≥0.0151 H/m), making it very suitable for precision applications. In compliance with GB/T 2101 standard, DT4C guarantees product quality and reliability. DT4C pure iron is a high-quality material suitable for a variety of electromagnetic applications, providing stable performance and reliability to meet customer needs.

| Grade | C | Si | Mn | P |

| DT4C | 0.0015~0.0016 | 0.000~0.0001 | 0.0181~0.0192 | 0.0033~0.0037 |

| S | Al | Cu | Cr | |

| DT4C | 0.0027~0.0033 | 0.0021~0.0068 | 0.006~0.0072 | 0.0070~0.0073 |

| Pure Iron Magnetic Properties | ||||

| DT4C | Hc(A/m):≤32 | △Hc(A/m):≤4 | Mm(H/m):≥0.0151 | Stand:GB/T 2101 |

|

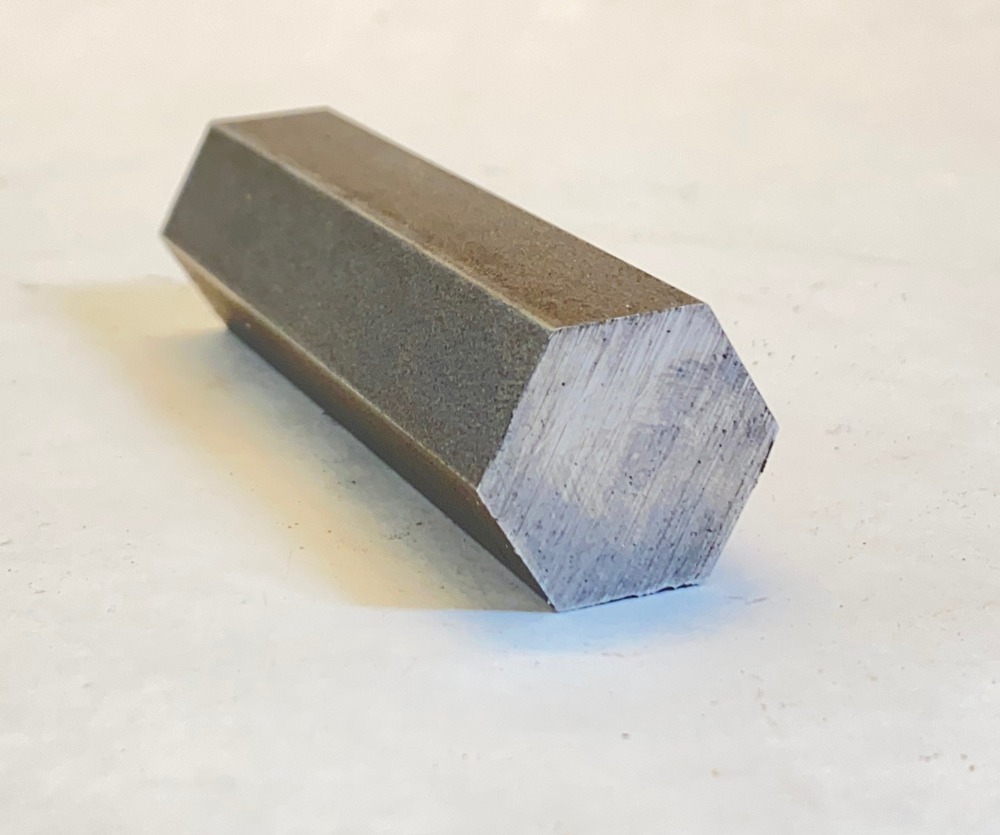

Product Show

|

Application

Pure iron for smelting is commonly used in the production of various special alloys, including master alloys, electrothermal alloys, hard magnetic alloys, low-carbon stainless steel, and powder metallurgy materials. It plays a crucial role in manufacturing high-purity iron-based materials for top-quality alloy products. The applications of this pure iron are vast across industries such as metal processing, electronics, automotive, and aerospace, showcasing its versatility and importance in modern manufacturing processes.

High-purity iron is essential for the production of magnetic materials such as ferrite magnets and NdFeB permanent magnets, which are widely used in electronics, electric machinery, medical equipment, toys, packaging, hardware machinery, aerospace, and other industries. The latest generation of rare earth NdFeB magnets, known as the strongest permanent magnets, are composed of rare earth metal neodymium (29%-32.5%), iron (63.95%-68.65%), non-metallic element boron, and additional alloys like dysprosium (0.6-8%), niobium (0.3-0.5%), aluminum (0.3-0.5%), copper (0.05-0.15%), among others. These magnetic materials play crucial roles in various industrial sectors, showcasing their importance in modern applications across different industries.

High-purity iron, known for its soft magnetic properties, offers easy magnetization and demagnetization, high saturation induction density, and low coercivity. This versatile material is extensively utilized in the manufacturing of electromagnetic devices and equipment, including electromagnetic relays, motors, and more, across industries such as aerospace, automotive, machinery manufacturing, electrical, and electronics. High-purity iron plays a vital role in enhancing the performance of electromagnetic equipment and meeting the diverse needs of various industries.

Features

Features of DT4E Electrical/Industrial Pure Iron

DT4C pure iron offers a high-purity composition with ultra-low levels of carbon (0.0015-0.0016%), sulfur, and phosphorus, ensuring exceptional quality and stability for precision applications.

Known for its superior electromagnetic properties, DT4C pure iron features low coercivity (≤32 A/m), high permeability, and strong saturation magnetic induction, providing consistent magnetic performance without aging. This makes it an ideal choice for electrical and industrial applications.

With excellent cold and hot processing capabilities, DT4C pure iron can withstand various processing methods such as turning, punching, bending, and drawing, with minimal redness sensitivity during hot processing, making it versatile across a wide temperature range in manufacturing.

The dense and uniform internal structure of DT4C pure iron, achieved through advanced smelting processes like RH refining and electromagnetic stirring, ensures low gas content, enhancing durability and magnetic performance.

DT4C pure iron also boasts a high-quality surface finish, enabling strong welding and electroplating performance, making it suitable for applications requiring a clean, polished appearance and robust structural integrity.

Compliant with industry standards such as GB/T 2101, DT4C pure iron guarantees reliable performance and consistent quality for demanding industrial and electrical applications.

FAQ

Q1: Can you send samples?

A: Of course, we can provide free samples to customers and provide global express service.

Q2: What product information do I need to provide?

A: Please provide the product grade, width, thickness, surface treatment requirements, and the quantity required to purchase.

Q3: This is my first time importing steel products, can you help me?

A: Of course, we have an agent to arrange the freight and we will handle it with you.

Q4: What are the shipping ports?

A: Normally, we ship from Shanghai, Tianjin, Qingdao, and Ningbo ports, you can specify other ports as needed.

Q5: What is the product price information?

A: Prices vary based on cyclical price changes of raw materials.