Phone / WhatsApp:

+86-13288385958

E-mail: sale20@shunbeifactory.com

E-mail: sale20@shunbeifactory.com

Xingye 9th Road, Guanglong Industrial Zone, Yongxing village, Chencun Town, Shunde District, Foshan City, Guangdong, China

DX53D+Z

600mm to 1500mm

Z30~Z275g/m2

zero/small/regular/big

AiSi, ASTM, bs, DIN, GB, JIS

Roll

Galvanised steel

10 TON

Construction

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

| The high strength hot dip DX53D+Z galvanized steel coil is a very good product of hot-dip galvanizing metal. This kind of metal is very good regarding anti-corrosion together with metallic property preservation. To keep the base metal, which is steel, from rusting, it is dipped in molten zinc creating a zinc coating barrier over the surface. It is a high strength and good rigidity material that caters to the industrial processing requirement. The specifications for our galvanized steel coils can be customized as per the customer’s requirement. However, generally, we deal in thickness varying from 0.2mm to 4.0mm with a width range of 600mm to 1500mm. | |||||||||

Product Detail

|

Product Description

The DX53D+Z Galvanized Steel Coil is a high-quality, hot-dip galvanized steel product renowned for its excellent corrosion resistance, formability, and diverse range of applications. This steel grade, adhering to the EN 10346 standard, is particularly suitable for forming operations and is widely used in various industrial sectors.

|

Surface Structure

The no spangle finish exhibits a smooth, uniform surface devoid of any visible zinc crystal patterns. This finish is ideal for applications requiring a sleek and consistent appearance. The small spangle finish features a subtle and refined zinc crystallization pattern, offering a balance between aesthetics and corrosion protection. The regular spangle finish, the most common type, displays a moderate and uniform zinc crystal pattern, providing a classic galvanized look. Finally, the big spangle finish boasts larger, more prominent zinc crystals, creating a distinctive and visually striking appearance.

The cross-sectional view of the coil, presented in the lower part of the image, reveals the layers that make up the Gi Coil DX53D+Z Galvanized Steel Coils. The base metal, typically cold-rolled steel, forms the core of the coil. It is then coated with a layer of zinc, which provides the primary corrosion protection. An additional chromium-free passivation coating is applied over the zinc layer to enhance the coil's resistance to oxidation and corrosion, ensuring long-lasting performance in various environments.

|DX53D+Z Chemical Element Content (%)

| Element | C | Si | Mn | P | S | Ti |

| Minimum | - | - | - | - | - | - |

| Maximum | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 |

Product Specification

Shunbei presents the Gi Coil DX53D+Z Galvanized Steel Coils, a product that combines quality and versatility for construction applications. Made from premium galvanized steel, these coils offer excellent durability and corrosion resistance. With a width range of 600mm to 1500mm, they cater to various project requirements.

The zinc coating, available from Z30 to Z275g/m2, ensures optimal protection against environmental elements. Choose from zero, small, regular, or big spangle finishes to match your desired look. These coils adhere to international standards, including AISI, ASTM, BS, DIN, GB, and JIS.Shunbei's Gi Coil DX53D+Z Galvanized Steel Coils come in roll form for easy handling and storage. With a minimum order quantity of 10 tons, we accommodate both small and large-scale projects. Our customization options allow you to tailor the coils to your specific needs.Backed by over 20 years of experience, Shunbei is dedicated to providing high-quality products and exceptional customer service. Our ISO certification ensures consistent quality and reliability. With efficient production and logistics, we offer competitive lead times of 10-35 days.

Trust Shunbei's Gi Coil DX53D+Z Galvanized Steel Coils for your construction projects and experience the difference of a reliable and experienced manufacturer.

Parameter | Value |

Model | DX53D+Z |

Surface Treatment | Galvanized |

Width | 600mm to 1500mm |

Zinc Coating | Z100 to Z600 (100-600 g/m²) |

Spangle | zero/small/regular/big |

Thickness | 0.3mm to 3.0mm |

Shape | Roll |

Material | Galvanized steel |

MOQ | 10 TON |

Usage/Application | Construction |

Customizability | Customizable |

Certification | ISO |

Origin | China |

Delivery Time | 10-35 Days |

Color | all RAL color as client’s request |

Payment Terms | T/T L/C and Western Union etc |

Standard | EN 10346 |

Product Image

|

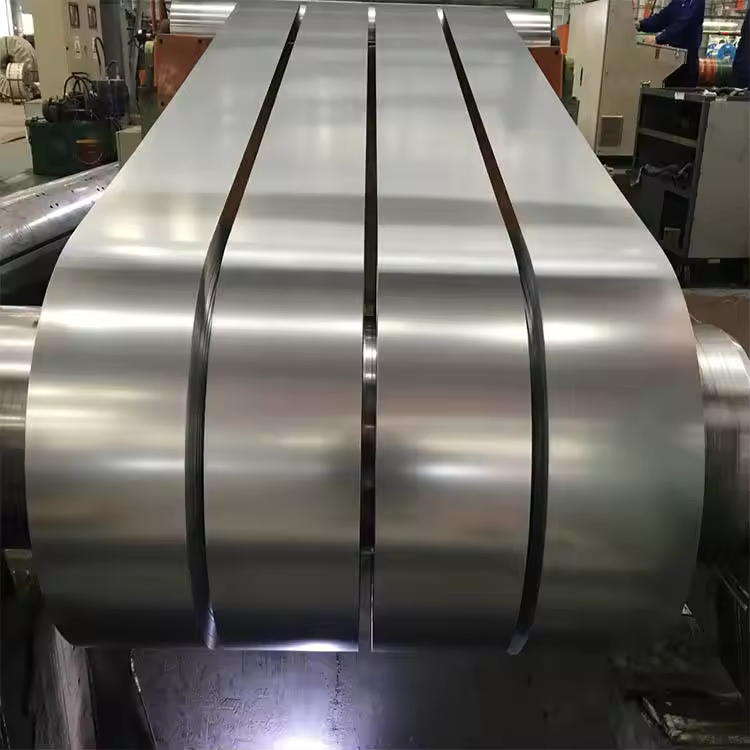

Product Display

Image depicts neatly stacked coils, highlighting the consistent and uniform appearance of the galvanized steel. The coils are well-organized and ready for distribution to customers. It also shows a close-up view of the coiled steel, revealing the smooth and even surface of the galvanized coating. This emphasizes the attention to detail and quality control measures employed by Shunbei to ensure a superior product.

Overall, the Product Display section communicates the quality and consistency of Shunbei's Gi Coil DX53D+Z Galvanized Steel Coils, instilling confidence in potential customers regarding the product's capabilities and the company's commitment to excellence.

Product Process

|

Product Process

Steel Making and Casting

Hot Rolling

Pickling

Cold Rolling

Annealing

Galvanizing

Post-Galvanizing Treatments

Quality Control

Slitting and Cutting

Packaging and Shipping

1.Steel Making and Casting

Raw Material Preparation: Iron ore, coke, and limestone are processed in a blast furnace to produce molten iron.

Basic Oxygen Furnace (BOF) or Electric Arc Furnace (EAF): The molten iron is converted into steel by removing impurities and adjusting the chemical composition.

Casting: The molten steel is then cast into slabs through a continuous casting process.

2.Hot Rolling

Reheating: The steel slabs are reheated to around 1200°C in a reheating furnace.

Rough Rolling: The reheated slabs pass through roughing mills to achieve preliminary thickness reduction.

Finish Rolling: Further rolling in the finishing mills reduces the thickness to the desired level, producing hot-rolled coils.

3.Pickling

Cleaning: The hot-rolled coils are cleaned in a pickling line using hydrochloric acid to remove the oxide scale formed during hot rolling.

4.Cold Rolling

Thickness Reduction: The pickled coils are cold rolled at room temperature to achieve precise thickness and improved surface finish. This process also enhances the mechanical properties of the steel.

5.Annealing

Batch Annealing or Continuous Annealing: The cold-rolled coils are annealed to restore ductility by recrystallizing the grain structure. Batch annealing is done in sealed furnaces, while continuous annealing involves passing the steel through a series of heating and cooling zones.

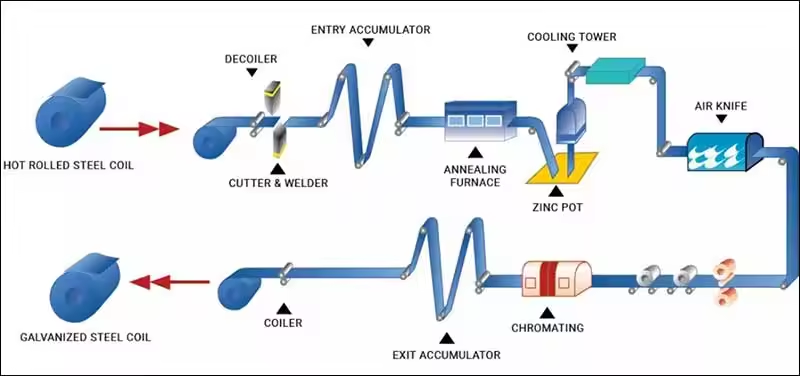

6.Galvanizing

Surface Preparation: The annealed coils are cleaned and prepped for galvanizing.

Hot-Dip Galvanizing: The steel passes through a molten zinc bath at temperatures around 450°C. This process coats the steel with a layer of zinc, providing corrosion resistance.

Air Knives: After exiting the zinc bath, the thickness of the zinc coating is controlled using high-pressure air knives.

7.Post-Galvanizing Treatments

Chromating or Passivation: To enhance corrosion resistance and adhesion properties for subsequent painting or coating, the galvanized steel may undergo chromatin or passivation treatments.

Oiling: Applying a thin oil layer helps protect the surface from corrosion during storage and transportation.

Skin Passing: A light rolling process improves surface finish and mechanical properties, reducing the appearance of defects such as fluting.

8.Quality Control

Inspection: The galvanized coils are inspected for coating thickness, surface quality, mechanical properties, and chemical composition to ensure compliance with standards.

Testing: Various tests, including tensile tests, elongation tests, and coating adherence tests, are conducted to verify the quality.

9.Slitting and Cutting

Slitting: The coils can be slit into narrower widths as per customer requirements.

Cutting to Length: The coils may also be cut into sheets of specified lengths.

10.Packaging and Shipping

Coil Packaging: The coils are carefully packaged to protect against physical damage and environmental exposure during transportation.

Shipping: The final products are then shipped to customers for various applications.

|

Product Packaging

Company Detail

|

Company Profile

Foshan Shunbei Ronghang Metal Manufacturing Co., Ltd.

is a leading integrated steel company with over two decades of experience in providing high-quality, competitively priced steel products to domestic and international markets. As a one-stop solution provider, we offer a comprehensive range of products, including seamless and welded steel pipes, galvanized steel coils, steel sheets, PPGI, stainless steel sheets, aluminum coils, angle bars, H steel beams, and deformed steel bars.Our main product is the Gi Coil DX53D+Z Galvanized Steel Coils. This represents a leap in quality and innovation. Produced by advanced hot-dipped galvanizing technology, it ensures the product has excellent corrosion resistance. Regarding spangle sizes, therefore, our Gi Coil DX53D+Z Galvanized Steel Coils are made to suit any aesthetic and performance requirement in any industry.

Our products find wide-ranging applications in the automotive industry, household appliances, construction sector, and highway guardrail construction, among others. The versatility and reliability of our offerings have earned us a strong reputation in the market, with annual sales surpassing 50 million tons.

Shunbei Ronghang Metal has established a significant presence both domestically and internationally. Our products are sold extensively in Northeast, North China, East China, and have made successful inroads into markets across Europe, the Middle East, Southeast Asia, and Australia. We take pride in serving customers in over 50 countries and regions worldwide.

|

Certifications