Phone / WhatsApp:

+86-13288385958

E-mail: sale20@shunbeifactory.com

E-mail: sale20@shunbeifactory.com

Xingye 9th Road, Guanglong Industrial Zone, Yongxing village, Chencun Town, Shunde District, Foshan City, Guangdong, China

DC51D

600mm to 1500mm

Z30~Z275g/m2

zero/small/regular/big

AiSi, ASTM, bs, DIN, GB, JIS

Roll

GI Steel

10 TON

Industrial

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

| Galvanized steel coils of DC51+Z are being made by hot dipping cold rolled base metal in strength and formability; it's exceptional and superior features are high and equal grades of corrosion resistance in zinc. Such a versatile range of materials is widely used in sectors such as construction, household appliances, automotive, and machinery construction. Due to its excellent workability and high endurance, DC51+Z is a preferred alternative in construction projects that may require both structural strength and long-term immunity against corrosion. | |||||||||

Product Description

|

Product Description

Shunbei is a committed Chinese Prime Cold Rolled Galvanized Steel Coil Hot Dip DC51+Z Manufacturers for several years. We are dedicated to producing custom sizes for our galvanized steel coil products. Our offerings are widely used in the construction, home appliance, and automotive industries. Inquire today!

Galvanizing layer of DC51+Z galvanized coil is uniform and tight. Cohesion and anticorrosion resistance are much better, thereby preventing the surface of the steel from oxidizing and corroding for a long service life. In addition to this, the pervaded layer is also very decorative so that it can give nice looks to whatever it is used for. The said cold-rolling base has excellent molding properties and soldering properties and can be processed by all kinds of molding technology such as stamping, bending, cutting etc.. This excellent processing property makes DC51+Z galvanized roll the ideal material for making various assemblies and parts.

|

Surface Structure

SUBSTRATE &ZN COATING LAYER

SUBSTRATE &ZN COATING LAYER The substrate is made of a high-quality cold-rolled steel plate with a flat surface and certain mechanical properties. It provides the strength and rigidity of the DC51+Z galvanized coil and provides a guarantee for the structural support and seismic performance of the product.

The galvanized layer is a layer of zinc formed on the surface of the substrate by the hot-dip galvanizing process. The galvanized coating is mainly composed of pure zinc and has a uniform and dense structure. It can effectively prevent oxidation and corrosion on the surface of the substrate and provide excellent corrosion resistance.

The galvanized layer of DC51+Z galvanized coil has good adhesion and is not easy to peel off. The thickness of the galvanized layer can be adjusted according to customer needs, generally between 20-60μm. Thicker galvanized layers can provide better corrosion resistance and are suitable for more severe environmental conditions.

Zn Coating layer

Cold-Rolled Steel

Zn Coating Layer

|

Surface types

a) No Spangle: This surface type features a smooth, uniform zinc coating without any visible spangle pattern, providing a sleek and consistent appearance.

b) Small Spangle: Small spangle surfaces exhibit a fine, dense pattern of zinc crystals, offering enhanced corrosion resistance and a visually appealing texture.

c) Regular Spangle: With a balanced distribution of medium-sized zinc crystals, regular spangle surfaces combine good corrosion protection with a traditional galvanized look.

d) Big Spangle: Characterized by large, distinct zinc crystals, big spangle surfaces create a bold, textured appearance while maintaining the durability and corrosion resistance of the galvanized coating.

Product Specification

Parameter | Value |

Grade | DC51+Z |

Standard | ASTM, AISI, EN, JIS |

Thickness | 0.3MM to 3.0MM |

Width | 600MM to 1500MM |

MOQ | 10 Ton |

Surface Finish | no spangle, small spangle, regular spangle, big spangle |

Coating | Zinc (Galvanized), Aluminum zinc magnesium, aluminum zinc |

Features

Corrosion Resistance:Galvanized Steel Coil is a low-cost and efficient way of protecting the steel against corrosion, which is used more frequently. As much as one-half of the total world production of zinc is consumed in this process. Zinc itself provides the steel with a very dense layer of protection and forms the basis for cathodic protection. Even if the zinc coating is scraped off, it would still inhibit the corrosion of iron-based materials through cathodic protection.

Good Cold Bending and Welding Performance:Mostly used is low carbon steel, which must exhibit good performance in cold bending to welding and certain performance when stamping.

Reflectivity: high reflectivity, making it a thermal barrier.

The coating is highly durable, the metallurgical structure formed by the zinc coating is such that it can bear any mechanical damage during handling and use.

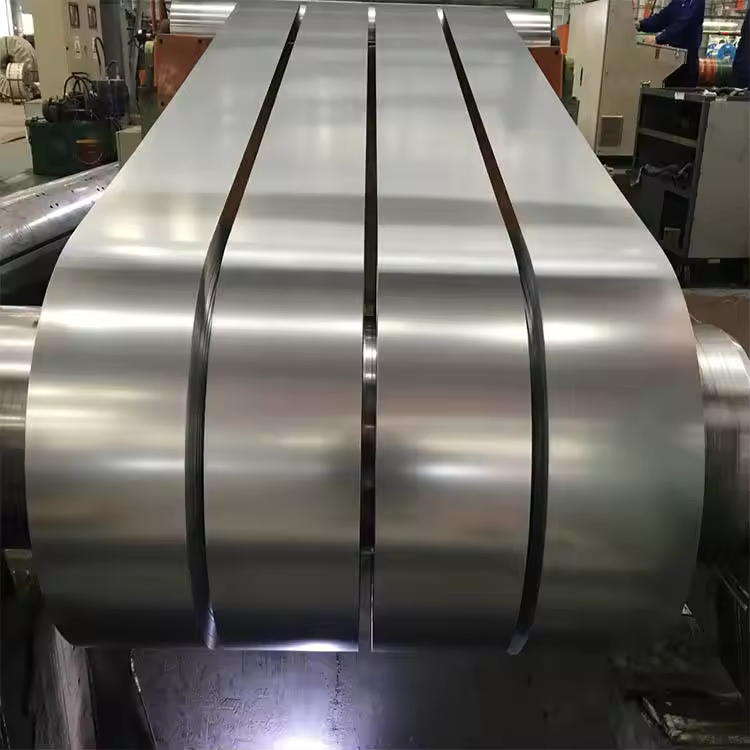

Product Image

|

Product Display

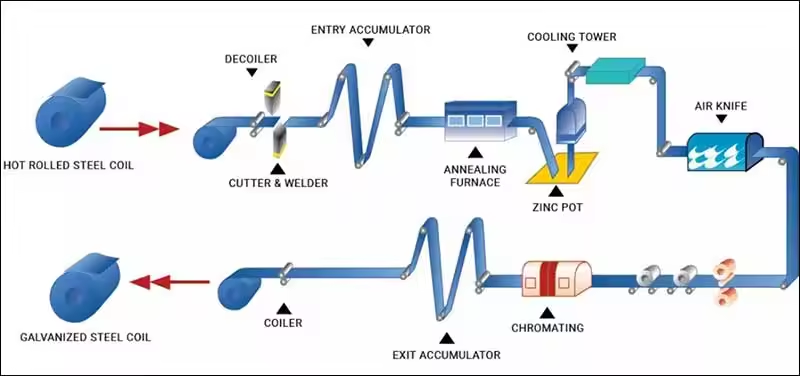

Product Process

|

Product Process

The production process of DC51+Z Galvanized Steel Coil involves several key steps. First, the cold-rolled steel coil undergoes a cleaning process to remove any impurities or contaminants. Next, the coil is immersed in a molten zinc bath, where a layer of zinc adheres to the steel surface through a hot-dip galvanizing process. The coil then passes through a series of cooling and leveling stages to ensure a uniform and consistent zinc coating. Finally, the galvanized steel coil is inspected for quality, coiled, and packaged for delivery to customers across various industries.

|

Product Packaging

Company Detail

|

Company Profile

Foshan Shunbei Ronghang Metal Manufacturing Co., Ltd , a prominent international steel production and marketing enterprise, seamlessly integrates production, sales, processing, distribution, and service. With extensive experience in high-quality steel research, development, and production, Shunbei-Metal has earned the trust of both domestic and foreign customers.

Boasting a team of 120 dedicated employees, including skilled professionals and technical experts, Shunbei-Metal maintains multiple warehouses in Guangdong, Shandong, and Qingdao to ensure ample inventory and prompt delivery. The company's state-of-the-art factory features six steel production lines and eight sets of processing equipment, enabling efficient processing, flattening, coating, heat treatment, cutting, drilling, chamfering, conditioning, and surface treatment. With an impressive annual output of 400,000 tons and a current inventory exceeding 1,000,000 tons, Shunbei-Metal guarantees optimal purchasing and production cycles for its customers.

Shunbei-Metal's comprehensive product range includes carbon steel plates, coils, galvanized plates, coils, color-coated steel coils, PPGI/PPGL, and various high-quality steel products. The company adheres to stringent GB, ASTM, JIS, and DIN standards, supported by advanced testing equipment and a robust technical team. Notably, Shunbei-Metal has forged long-term partnerships with renowned domestic steel mills and holds prestigious certifications such as SGS, CE, and ISO.

With a global presence and strong ties with customers across Europe, South America, North America, Asia, and the Middle East, Shunbei-Metal welcomes visitors from around the world to its factory, fostering mutually beneficial collaborations.

|Certificate

|

FAQ

Q: Are you trading company or manufacturer ?

A: We are a manufacturer since 2008 year, we have been approved by LY, BV, DNV, KR, NR, RINA, TMCP, ABS, CCS certficate and CE ISO and OHSAS certificate.

Q: How long does your delivery time take?

A: The annual output of our factory is 400,000 tons, and the current inventory is more than 100,000 tons. Delivery time is 3-15days.

Q: Does the product have quality inspection before loading?

A: Normally we support LY, BV, DNV, KR, NR, RINA, TMCP, ABS, CCS, SGS inspection. You can also send your tester to come. Welcome to our factory to supervise quality.

Q:what services can we provide?

Q:The product quality meets the standards?