Phone / WhatsApp:

+86-13288385958

E-mail: sale20@shunbeifactory.com

E-mail: sale20@shunbeifactory.com

Xingye 9th Road, Guanglong Industrial Zone, Yongxing village, Chencun Town, Shunde District, Foshan City, Guangdong, China

10 TON

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

| PREPAINTED GALVANIZED STEEL CORRUGATED ROOF PLATE | SHUNBEIFACTORY Thickness: 0.12MM-0.7MM Width: 600mm-1500mm Length:1000-6000mm Grade:SGCC,SGCH,G350,G450,G550,DX51D,DX52D,DX53D Zinc Coating:40g/m2 to 275g/m2 Size & Color : Support customized size and color Surface: Galvanized/PVC,Black and color painting/Transparent oil,anti-rust oil/According to clients requirement Min Order: 3~5 TON Stock: Yes Samples: Free Payment:T/T, LC Delivery Time:Usually within 10-15days after receipt of advance payment. Application: Mold & Dies, Ship Plate, Boiler Plate, Container Plate, Flange Plate. | |||||||||

PRODUCT DESCRIPTION

|

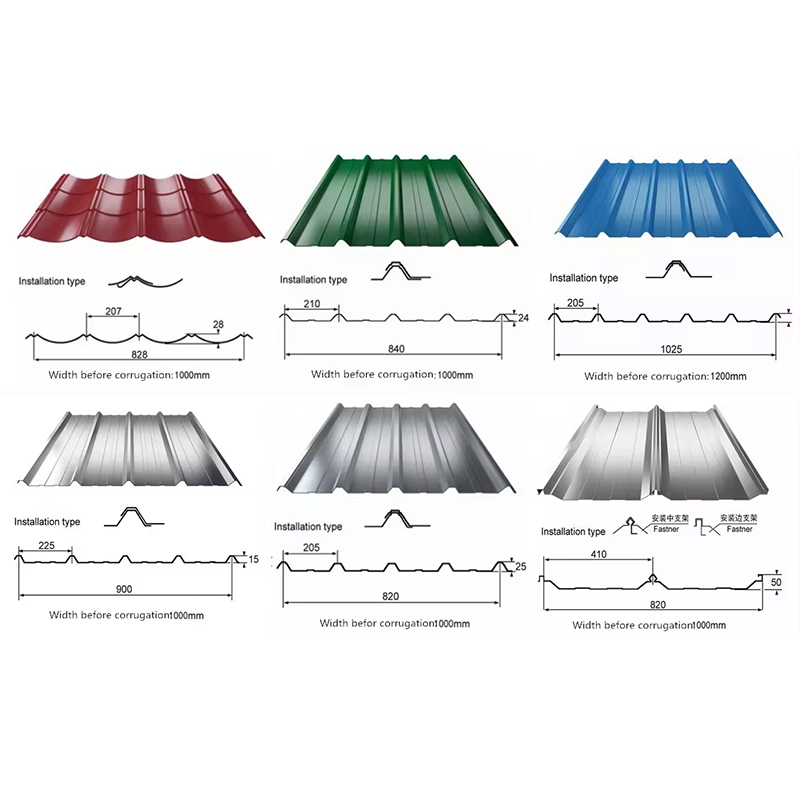

PRODUCT SPECIFICATIONS

COLOUR COATED STEEL SHEET | SHUNBEIFACTORY

Thickness: 0.12MM-0.7MM

Width: 600mm-1500mm

Color:Standard or customized

Shape: Wave Tile, T-Shaped Tile

Min Order: 3~5 TON

Stock: YesApplication: Mold & Dies, Ship Plate, Boiler Plate, Container Plate, Flange Plate.

|

PRODUCT INTRODUCTION

Traditional coatings can be divided into several categories. The most advanced is fluorocarbon coating, which can prevent corrosion for nearly 20 years. It is usually distributed from steel mills to various places in the form of rolls. The color-coated steel plates we often see refer to processed plates with a thickness of about 50~100mm. They are composed of fillers in the middle and color-coated steel plates on both sides. Among them, the thickness of the color plate is 0.4mm, 0.5mm, 0.6mm and other different thicknesses. Due to the special profile, the construction speed of the factory built with color-coated steel plates is very fast (for example, the roof of the African factory is made of color-coated plates), but the strength is low. The base materials of color-coated steel plates are cold-rolled base materials, hot-dip galvanized base materials and electro-galvanized base materials. The types of coatings can be divided into polyester, silicon-modified polyester, polyvinylidene fluoride and plastic slurry. The surface state of color-coated steel plates can be divided into coated plates, embossed plates and printed plates.

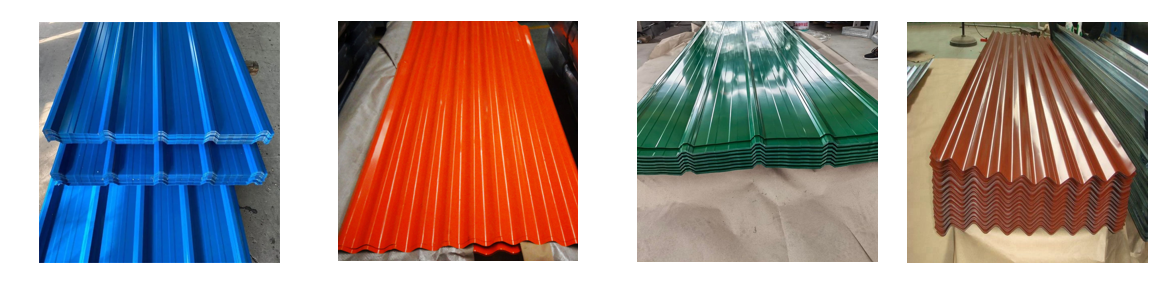

PRODUCT SHOW

|

PRODUCT SHOW

PRODUCT APPLICATION

|

PRODUCT APPLICATION

Steel structure factory>> Color-coated steel plates are often used for the roofs, walls, doors and windows of steel structure factories.

Airports>>Used for the roofs, exterior walls and interior decoration of buildings such as airport terminals and hangars.

Warehouses and frozen warehouses>> Due to its good corrosion resistance and colorful decorative effects, it is widely used in the roofs and walls of warehouses and frozen warehouses.

Industrial and commercial buildings>> Such as the exterior walls and roofs of factories, warehouses, large shopping malls, office buildings, etc.

Home appliance shells>> Color-coated steel plates are used to produce the shells of various home appliances, such as refrigerators, washing machines, air conditioners, etc., because they are corrosion-resistant, durable and beautiful.

Automotive exterior structural parts>> Used for the exterior panels and carriages of vehicles, providing weather resistance and aesthetic effects.

Containers and trucks>> Color-coated steel plates are used as the exterior materials of containers and truck carriages, and have strong weathering resistance and durability.

Doors, windows and fences>> Used in the production of various doors, windows and fences, which have both anti-corrosion properties and can provide a rich variety of color options.

Product Advantages

|

PRODUCT ADVANTAGES

Strong earthquake resistance >> Suitable for areas with earthquake intensity above 8 degrees. The light steel roof truss structure used in low-rise villas has stronger earthquake resistance and can effectively resist horizontal loads and ensure structural safety.

Excellent wind resistance>>Light weight, high strength, strong overall rigidity and outstanding wind resistance. It can withstand hurricane winds of 70 meters per second, ensuring the stability of buildings in extreme weather and protecting lives and property.

Service life>>Using super anti-corrosion cold-rolled galvanized sheet to avoid corrosion problems and extend service life. The design life of the color steel structure can reach 100 years, making it long-term reliable.

Excellent thermal insulation>>The color steel sandwich panel uses fiberglass wool insulation material to provide excellent thermal insulation effect. The insulation board with a wall thickness of 100mm is equivalent to a 1m thick brick wall, which significantly improves energy efficiency.

Outstanding sound insulation effect >> Color steel + light steel system windows use insulating glass, and the sound insulation effect can reach more than 40 decibels. The sound insulation effect of the wall composed of light steel keels, insulation materials and gypsum boards is as high as 60 decibels, ensuring a comfortable living environment.

Healthy and environmentally friendly >> Green building materials are used to meet ecological and environmental requirements, and the materials are 100% recyclable, reducing waste pollution and ensuring the health of residents.

Improved comfort >> The efficient and energy-saving wall system has air conditioning function, and the roof ventilation design ensures air circulation in the house and optimizes the indoor environment.

Fast construction >> adopts dry construction method and is not subject to seasonal restrictions. A 300-square-meter building requires only 5 workers and 30 working days to complete the construction, shortening the construction period and reducing costs.

Environmental protection and energy saving >> All use high-efficiency and energy-saving walls, which have excellent thermal insulation, heat insulation and sound insulation effects, and can achieve energy-saving standards of up to 50%, helping to save energy and protect the environment.

Product Brochure