Phone / WhatsApp:

+86-13288385958

E-mail: sale20@shunbeifactory.com

E-mail: sale20@shunbeifactory.com

Xingye 9th Road, Guanglong Industrial Zone, Yongxing village, Chencun Town, Shunde District, Foshan City, Guangdong, China

DC51

1mm to12m or As required

Z30~Z275g/m2

zero/small/regular/big

AiSi, ASTM, bs, DIN, GB, JIS

GI Steel

0.5-1.0mm

10 TON

Construction

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

| DC51 galvanized sheet is top-notch hot-dip galvanized steel. It boasts outstanding resistance to corrosion and high strength and hardness. Of iron, zinc, and carbon, it finds wide applications in automobile manufacturing, construction, and furniture production. Its tough surface presents durability and resistance to environmental factors, while its great weldability and formability allow fashions of all complexity to be fashioned from it. Such a flexible material, high in strength but easy to process, would be much sought after by industries where strength is required but also ease of outflow. | |||||||||

Product Description

DC51 galvanized sheet offers outstanding weldability and formability, making it well-suited for a wide range of complex shapes and fabrication processes. Its superior strength and durability ensure long-lasting performance, while its excellent corrosion resistance provides added protection in harsh environments. The sheet maintains stable quality throughout production, which has earned it widespread recognition across various industries. As a result, DC51 galvanized sheet is considered an ideal material for both construction and industrial applications, offering reliability, versatility, and ease of use for numerous projects.

|

Product Structure

Zn Coating Layer

Cold-Rolled Steel Sheet

Zn Coating Layer

|

Chemical Composition

| Element | Composition (%) |

| Carbon (C) | ≤0.10 |

| Silicon (Si) | ≤0.05 |

| Manganese (Mn) | ≤0.50 |

| Phosphorus (P) | ≤0.035 |

| Sulfur (S) | ≤0.035 |

Product Specification

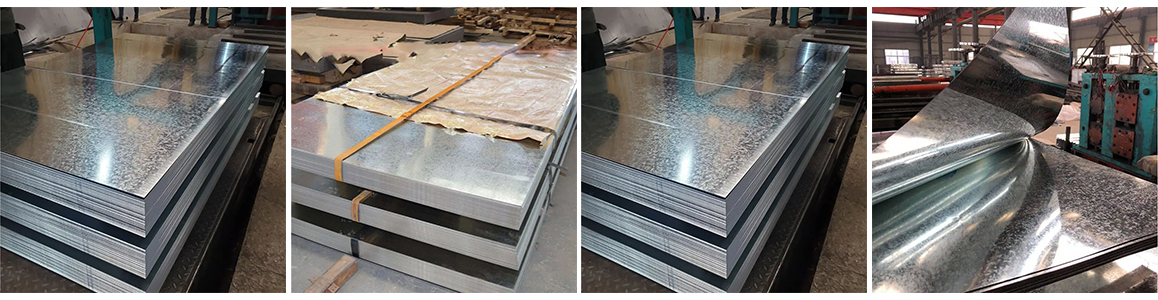

Product Display

|

Product Show

|

Application

DC51 galvanized sheet is widely used in automobile manufacturing due to its high strength, durability, and excellent corrosion resistance. It is ideal for producing various automobile components such as bodies, chassis, doors, panels, and structural parts. The sheet’s robust mechanical properties ensure that it can withstand the stresses and strains of daily use, providing enhanced protection and support for the vehicle's structure. Additionally, the galvanized coating helps prevent rust and extends the lifespan of automotive parts, making DC51 galvanized sheet an essential material in the production of reliable, long-lasting vehicles.

DC51 galvanized sheet is extensively used in the construction field for a wide range of applications. It is commonly found in building structures, roofs, walls, pipes, and doors, as well as windows. The sheet's excellent corrosion resistance ensures long-lasting durability, even in harsh weather conditions. Its good processing properties allow for easy fabrication into various shapes and sizes, making it highly versatile for different construction needs. With its ability to withstand environmental stress and maintain structural integrity, DC51 galvanized sheet is a reliable and cost-effective choice for construction materials, enhancing both the strength and longevity of buildings and infrastructure.

DC51 galvanized sheet is widely used in the production of home appliances, including appliance shells, furniture frames, and other components. Its smooth and flat surface makes it easy to paint and process, providing a clean, aesthetically pleasing finish. The sheet’s excellent durability ensures long-lasting performance, making it ideal for manufacturing appliances that require both visual appeal and resilience against wear and tear. Its corrosion resistance further contributes to maintaining the quality and longevity of the finished products.

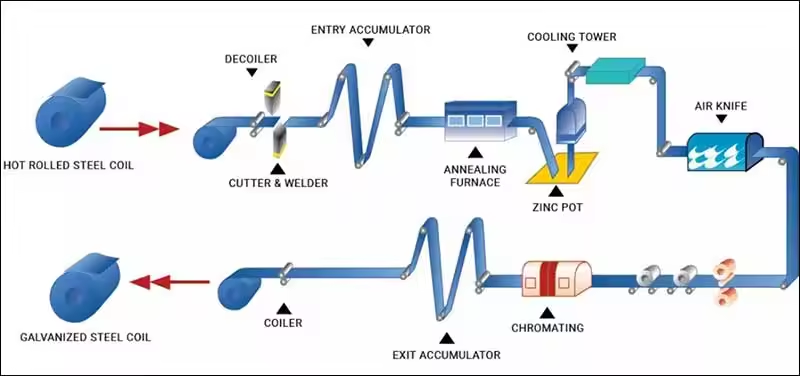

Production Process

|

Product Process

After the steel coil is delivered to the flattener and a continuous reduction operation from a number of rolling processes, the skin pass on the surface of the steel coil is reduced stepwise by a rotary set of rollers. This flattening apparatus mostly comprises many sets of these rollers. By means of different sets of rollers, the surface gets successively flattened on the steel coil; finally, this treated sheet is passed through the process of hot-dip galvanizing in which a zinc layer gets coated over the surface of this sheet. The specific procedure involves dipping the steel sheet into molten zinc liquid so that an even layer of zinc forms on its surface, thereby enhancing its corrosion resistance.

|

Product Packaging

Company Details

"Shunbei Ronghang" is a modern integrated enterprise specializing in the wholesale, storage, and distribution of Galvanized Steel, Galvalume Steel, Prepainted Steel, Cold rolled Steel, Hot rolled steel coils/plates, and steel pipes. Located in GuangDong Province, a major steel trading center in China, Shunbei Rongh operates on the principles of equality, mutual benefit, and win-win cooperation.

With a focus on building extensive and friendly business relationships in both domestic and overseas markets, Shunbei Rongh has established a strong customer base of over 200 fixed users, with annual sales exceeding 200,000 tons of steel products.

|

Certifications