Phone / WhatsApp:

+86-13288385958

E-mail: sale20@shunbeifactory.com

E-mail: sale20@shunbeifactory.com

Xingye 9th Road, Guanglong Industrial Zone, Yongxing village, Chencun Town, Shunde District, Foshan City, Guangdong, China

Dx54d+Z

600mm to 1500mm

Z30~Z275g/m2

zero/small/regular/big

AiSi, ASTM, bs, DIN, GB, JIS

Roll

GI Steel

10 TON

Industrial

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

| High-formability galvanized steel coil made from DX54D+Z grade with excellent deep drawing performance and corrosion protection. Ideal for automotive panels, appliance housings, and cold-formed products. | |||||||||

PRODUCT DESCRIPTION

|

PRODUCT DESCRIPTION

DX54D+Z galvanized steel coil is a hot-dip zinc-coated low-carbon steel product conforming to EN 10346. Known for its extra-deep drawing ability and smooth surface quality, DX54D is specifically developed for demanding cold-forming applications such as automotive inner panels, washing machine drums, or HVAC housings.

The +Z refers to a hot-dip zinc coating (typically Z100–Z275), which enhances corrosion resistance, improves longevity in humid environments, and allows for secondary processing such as painting, punching, and welding.

|

SURFACE STRUCTURE

Zinc layer

Cold-Rolled Steel

Zn Coating Layer

DX54D+Z galvanized steel coils

Dx54D+Z galvanized steel coil adopts hot dip galvanizing process to form a uniform zinc layer on the surface of the steel substrate, providing excellent corrosion protection. Its "D" series stands for deep drawing performance and is suitable for higher deformation processes. The surface can be provided in various forms such as skin passed, passivated, oiled, dried or chemically treated according to customer needs.

|THE SURFACE OF GALVANIZED STEEL COILS CAN BE DIVIDED INTO FOUR TYPES

No Spangle:The galvanized steel coil’s surface with no pattern is indistinct zinc grains while the entire surface has a smooth appearance.

Small Spangle:The surface of the small-pattern galvanized steel coil is fine zinc grains with a fine pattern.

Regular Spangle:The surface of the galvanized steel coil displays medium-sized zinc grains in a regular pattern.

Big Spangle:It exhibits a larger pattern since it has larger zinc grains on the surface of the galvanized steel coil.

PRODUCT SPECIFICATIONS

| Base Material | Hot-dip galvanized steel (DX51D, SGCC, S280GD–S550GD) |

| Zinc Coating | Z40 – Z275 g/m² |

| Paint Coating | Top side: 10–25μmBack side: 5–10μm |

| Coating Types | PE, SMP, HDP, PVDF |

| Color Options | RAL color chart / Custom color matching |

| Coil Weight | 3 – 8 tons (customizable) |

| Coil ID | 508mm / 610mm |

| Available Thickness | 0.12mm – 1.2mm |

| Available Width | 600mm – 1250mm |

| Length | Coil form / Custom sheet cut |

|

APPLICATION

DX54D+Z galvanized steel coils are used in cold forming and stamping applications where high ductility and consistent surface quality are essential. Typical uses include:

Automotive inner body parts – door panels, trunk lids, reinforcement plates

White goods & appliances – washing machine drums, refrigerator panels, oven bodies

HVAC & ventilation systems – air ducts, housings, metal frames

Electrical enclosures & cabinets

Cold-formed profiles – furniture structures, storage systems

Packaging and metal forming products

With its combination of formability, weldability, and corrosion resistance, DX54D+Z is one of the most versatile materials for precision stamped and formed parts.

MECHANICAL PROPERTIES

Performance Item Value (Typical Value)

Yield Strength (Rp0.2) ≤ 140 MPa

Tensile strength (Rm) 270 – 380 MPa

Elongation A80 ≥ 38%

Bending performance 180° crack-free bending (T≤2mm)

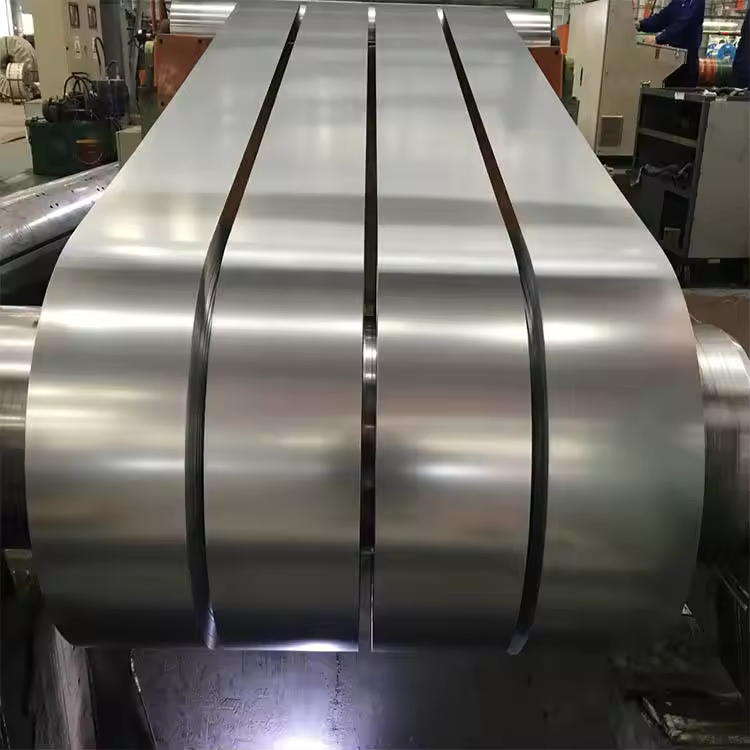

PRODUCT SHOW

|

PRODUCT DISPLAY

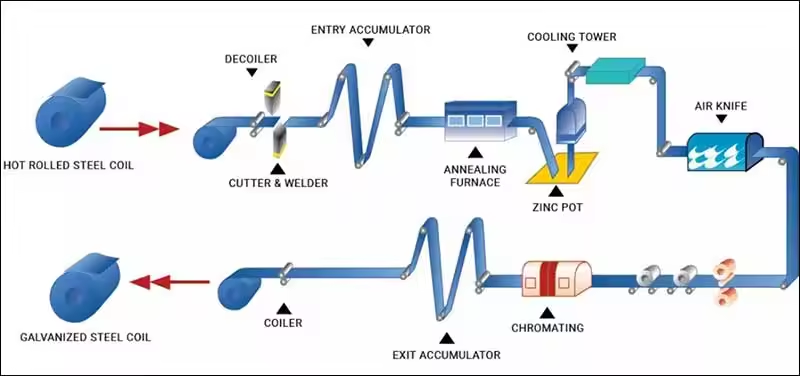

PRODUCT PROCESS

|

PRODUCT PROCESS

Raw material selection: low carbon cold rolled steel coil as base material

Cleaning and annealing: improve surface and formability through pickling and annealing

Hot dip galvanizing: the steel coil passes through the molten zinc pot to achieve zinc coating

Air knife zinc control: the air knife controls the uniform thickness of the zinc layer

Surface treatment: passivation, oiling or chemical passivation treatment

Coiling and packaging: customized weight, marking and packaging according to customer requirements

|

Product Packaging