Phone / WhatsApp:

+86-13288385958

E-mail: sale20@shunbeifactory.com

E-mail: sale20@shunbeifactory.com

Xingye 9th Road, Guanglong Industrial Zone, Yongxing village, Chencun Town, Shunde District, Foshan City, Guangdong, China

10 TON

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

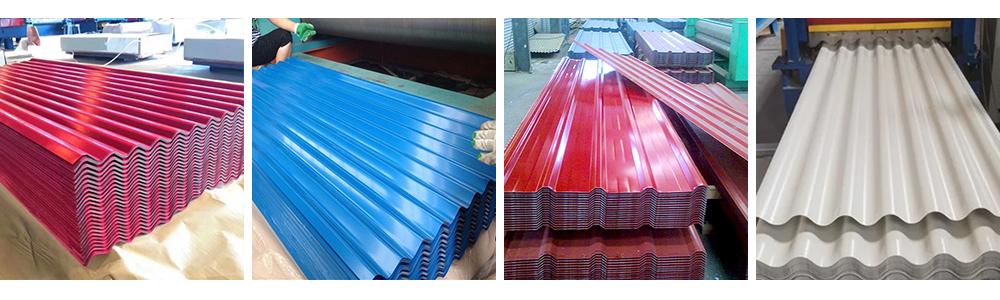

| DC51D+AZ GALVANIZED CORRUGATED ROOF PLATE | SHUNBEIFACTORY Thickness: 0.12MM-0.7MM Width: 600mm-1500mm Length:1000-6000mm Grade:DX51D+AZ;SGLCC;CS type B;DX51D+AZ;DC51D+AZ;G2+AZ Zinc Coating:40g/m2 to 275g/m2 Size & Color : Support customized size and color Min Order: 3~5 TON Stock: enough Samples: Free Payment:T/T, LC Delivery Time:Usually within 10-15days after receipt of advance payment. Application: Mold & Dies, Ship Plate, Boiler Plate, Container Plate, Flange Plate. “CUSTOMIZED COLOR-COATED CORRUGATED SHEET, CONSULT NOW~” | |||||||||

Product Brochure

PRODUCT DESCRIPTION

|

PRODUCT DESCRIPTION

Thickness: 0.12MM-0.7MM

Width: 600mm-1500mm

Color:White;Blue;red

Shape: Wave Tile, T-Shaped Tile or customized

Min Order: 3~5 TON

Stock: YesApplication: Advertising, construction, home appliance, electrical appliance, furniture and transportation industries

|

PRODUCT INTRODUCTION

Color-coated galvanized steel sheet is a common building material. Color-coated steel sheet is a product made of hot-dip galvanized steel sheet, hot-dip aluminum-zinc steel sheet, electro-galvanized steel sheet, etc., which is coated with one or several layers of organic coating on the surface after surface pretreatment (chemical degreasing and chemical conversion treatment), and then cured by baking. It is named after the colored steel coils coated with organic coatings of various colors, and is referred to as color-coated coils. In addition to the protection of the zinc layer, the organic coating on the zinc layer of the color-coated steel strip using hot-dip galvanized steel strip as the base material has a covering and protective effect to prevent the steel strip from rusting. The service life is longer than that of galvanized strip, about 1.5 times.

|

CHEMICAL COMPOSITION

| Element | Composition (%) |

| Carbon (C) | 0.18 |

| Silicon (Si) | 0.5 |

| Manganese (Mn) | 1.2 |

| Phosphorus (P) | 0.12 |

| Sulfur (S) | 0.045 |

| Titanium(Ti) | 00.3 |

|

PRODUCT APPLICATION

Roofs, walls, garages, warehouses

Refrigerators, air conditioners

Billboards

Bus stops, garages, parking lots

COATING TYPE

|

Company Profile

Polyester( )Good adhesion, rich colors, wide range in formability and outdoor durability, medium chemical resistance, low cost.

Silicon modified polyester(SMP), good hardness, wear resistance and heat resistance of the coating, as well as good exterior durability and resistance to chalking, gloss retention, average flexibility, medium cost.

High durability polyester(HDP), excellent color retention and UV resistance, excellent outdoor durability and resistance to chalking, good film adhesion, rich colors, excellent cost performance.

Polyvinylidene fluoride(PVDF), excellent color retention and UV resistance, excellent outdoor durability and resistance to chalking, excellent solvent resistance, good formability, dirt resistance, limited colors, high cost.

PRODUCT CATEGORIES

|

COLOR COATED COIL SUBSTRATE CLASSIFICATION

The product obtained by applying organic coating on hot-dip galvanized steel sheet is hot-dip galvanized color-coated sheet. In addition to the protective effect of zinc, the organic coating on the surface of hot-dip galvanized color-coated sheet also plays a role in isolation protection and rust prevention, and its service life is longer than that of hot-dip galvanized sheet. The zinc content of hot-dip galvanized substrate is generally 180g/m2 (double-sided), and the maximum galvanizing amount of hot-dip galvanized substrate for building exterior is 275g/m2.

Hot-dip aluminum-zinc steel sheet (55% Al-Zn) is used as the new coating substrate, usually containing 150g/㎡ (double-sided). The corrosion resistance of hot-dip aluminum-zinc sheet is 2-5 times that of hot-dip galvanized sheet. Continuous or intermittent use at temperatures as high as 490℃ will not cause serious oxidation or scale. The ability to reflect heat and light is twice that of hot-dip galvanized steel sheet, and the reflectivity is greater than 0.75, which is an ideal building material for saving energy.

The product obtained by using electrogalvanized sheet as substrate, coating with organic coating and baking is electrogalvanized color-coated sheet. Since the zinc layer of electrogalvanized sheet is thin, the zinc content is usually 20/20g/m2, so this product is not suitable for outdoor use in making walls, roofs, etc. However, due to its beautiful appearance and excellent processing performance, it can be mainly used in home appliances, audio, steel furniture, interior decoration, etc.

PRODUCT FEATURES

|

COLOR COATED COIL SUBSTRATE CHARACTERISTICS

Electrogalvanized substrate>>The coating is thinner and the corrosion resistance is not as good as that of hot-dip galvanized substrate;

Hot-dip galvanized substrate>>The thin steel plate is immersed in a molten zinc bath to make a layer of zinc adhere to its surface. This galvanized plate has good paint adhesion and weldability.

Hot-dip aluminum-zinc substrate>>This product has a 55% AL-Zn coating and has excellent corrosion resistance. Its service life is more than four times that of ordinary galvanized steel plates. It is a replacement product for galvanized plates.

Product features:

(1) It has good durability and longer corrosion resistance than galvanized steel plates;

(2) It has good heat resistance and is less likely to change color at high temperatures than galvanized steel plates;

(3) It has good heat reflectivity;

(4) It has similar processing and spraying properties to galvanized steel plates;

(5) It has good welding performance.

(6) It has a good performance-price ratio, durable performance and a very competitive price. Therefore, architectural designers, engineers and manufacturers have been widely using galvanized steel sheets in industrial buildings, steel structures and civil facilities, such as garage doors, eaves gutters and roofs.