Phone / WhatsApp:

+86-13288385958

E-mail: sale20@shunbeifactory.com

E-mail: sale20@shunbeifactory.com

Xingye 9th Road, Guanglong Industrial Zone, Yongxing village, Chencun Town, Shunde District, Foshan City, Guangdong, China

SGCC

600mm to 1500mm

Z30 to Z275g/m2

zero/small/regular/big

AiSi, ASTM, bs, DIN, GB, JIS

Roll

GI Steel

10 TON

Industrial

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

| Premium SGCC galvanized steel coils combine superior corrosion resistance with exceptional formability, available in thicknesses from 0.12mm to 4.0mm and widths ranging from 600mm to 1500mm. We offer comprehensive customization options through our OEM & OBM services, including specialized coating treatments and surface finishes to meet specific requirements. These versatile coils serve diverse applications across construction, industrial manufacturing, automotive, and home appliance sectors, backed by rigorous quality control and professional technical support. | |||||||||

Product Description

|

Product Description

Shunbei is a professional Chinese SGCC Galvanized Steel Coils manufacturer with years of expertise. We specialize in custom specifications from 0.12mm to 4.0mm thickness with various coating treatments. Our products serve extensively in construction, automotive, and industrial manufacturing sectors. Contact us now!

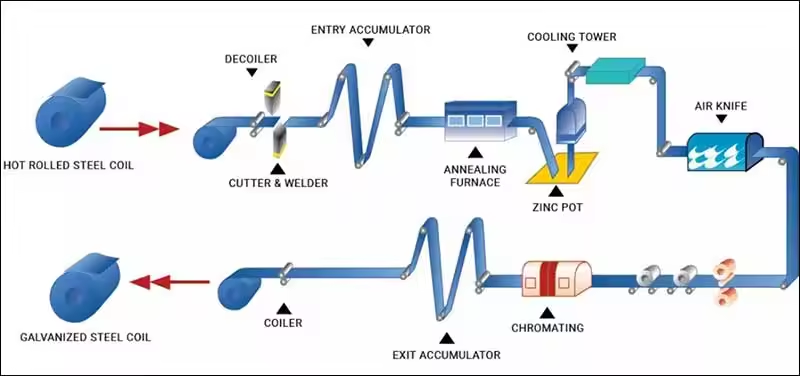

The SGCC galvanized coil is a product of steel coil which has been galvanized by the hot-dip process. It uses cold-rolled steel coil as its base material, and applies pre-treatment processes which include pickling, degreasing, and drying before immersing the steel coil in molten zinc liquid for galvanizing.

The surface zinc coating can isolate the steel from the outside air and anti-corrosion properties can be performed. The zinc layer is able to establish a tight oxide film in the atmosphere on the surface, thereby enhancing its corrosion resistance.

The surface after galvanizing of SGCC galvanized coil has high finish and good flatness with the application fields’ surface quality requirements. It also has good plasticity and weldability so that it can be processed, and welded easily and can vary numerous processing methods.

SGCC galvanized coil is generally applied in building decoration as well as household appliances, automobile manufacturing, and the manufacture of electronics and their components. Such products include roofs, walls, refrigerators, air conditioners, and parts of the automobile, among others.

|

Surface Structure

Galvanized coating thickness is typically selected based on varied application needs; usually, it is between 20-120 g/m². The more the thickness, the more enhanced the galvanized layer's corrosion resistance and durability. The surface structure of the galvanized coil consists of the primer layer, the galvanized layer, and the topcoat layer, which is divided into an outer pure zinc layer and an inner iron-zinc alloy layer. It is this structure that gives the galvanized coil outstanding corrosion resistance and surface quality, therefore enjoying popularity in many application fields.

Outer pure zinc layer: The outer pure zinc layer is the first layer on the surface of the galvanized coil, which has good corrosion resistance and finish. The pure zinc layer can form a dense oxide film in the atmosphere, which plays an anti-corrosion role and gives the surface a bright appearance.

Substrate layer: The substrate layer is the steel base of the galvanized coil, and a cold-rolled steel coil is usually used as the substrate. After pre-treatment processes such as pickling, degreasing, and drying, the cold-rolled steel coil has a flat surface and high surface quality.

Galvanized layer: The galvanized layer is an important part of the galvanized coil. It is formed by immersing the substrate in molten zinc liquid for galvanizing. The galvanized layer is mainly composed of zinc and is usually divided into two layers: the outer layer is a pure zinc layer and the inner layer is an iron-zinc alloy layer.

|

Surface Types

No Spangle surface features an ultra-smooth finish with minimal crystallization pattern. This premium surface type is specifically designed for applications requiring excellent paintability and superior aesthetic appearance, making it ideal for architectural panels and high-end appliance casings.

Small Spangle surface exhibits a fine, uniform crystalline pattern. This surface type delivers optimal formability and consistent zinc coating distribution, particularly suitable for automotive components and precision-engineered parts.

Regular Spangle offers a balanced crystalline structure with standard finish characteristics. As our most versatile surface option, it meets a wide range of industrial applications while maintaining excellent corrosion resistance and cost-effectiveness.

Big Spangle presents a distinctive, traditional galvanized appearance with pronounced crystal patterns. This surface type provides enhanced corrosion protection and is particularly popular in construction applications where traditional galvanized aesthetics are desired.

All surface types meet SGCC standards and undergo rigorous quality control to ensure consistent coating adhesion and appearance.

Product Specification

Parameter | Value |

Grade | SGCC |

Type | Steel Coil |

Surface Treatment | Galvanized |

Thickness | 0.12mm to 3.0mm (customizable) |

Width | 600mm to 1500mm |

Zinc Coating | 30-270g/m² |

Minimum Order Quantity | 10 tons |

Technique | Hot Rolled |

Surface | Black |

Spangle | Zero, Regular, Big |

Certificate | SGS, BV, MTC, ISO |

Coil Weight | 3-8 tons |

Brand | Shunbei |

Origin | China (Mainland) |

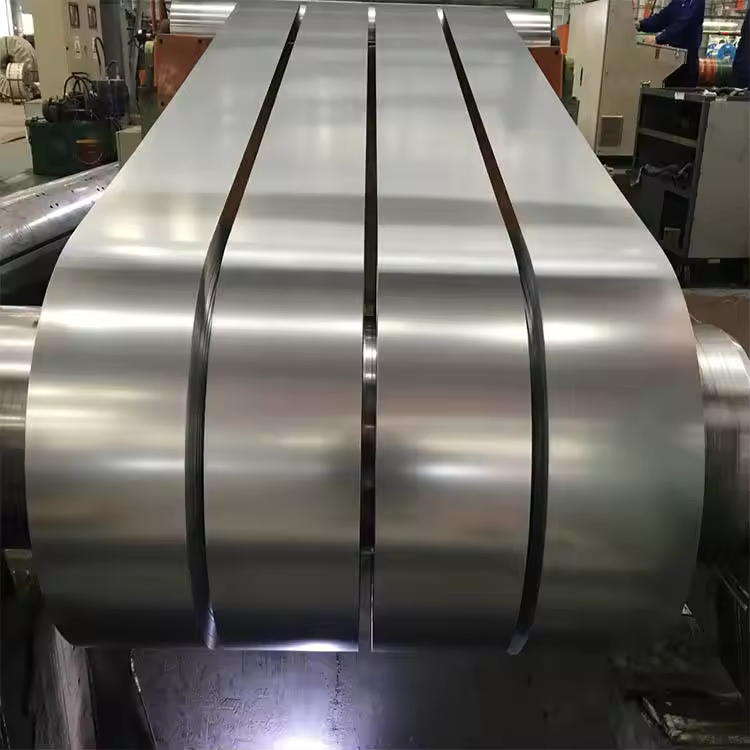

Product Image

|

Product Display

Product Process

|

Product Process

|

Product Packaging

Company Detail

|

Company Profile

SHUNBEI RONGHONG Metal Co., Ltd. is a renowned industry-leading enterprise specializing in the import and export of high-end plates, establishing itself as a prominent player in the metal circulation field. Headquartered in Tianjin, China, our company is widely recognized as a trusted and reliable steel service provider.

We offer a comprehensive range of products, including seamless steel pipes, stainless steel pipes, wear-resistant plates, stainless steel plates, stainless steel coils, and other specialized alloy materials. Our products adhere to international standards such as DIN/EN, ASTM/ASME, DIN, and JIS, and can be tailored to meet specific customer requirements. Available in various forms such as tubes, plates, tapes, and rolls, our product portfolio caters to diverse industry needs.

Through strategic collaborations with major domestic and international steel mills, we have established a robust supply chain network, ensuring a substantial inventory of imported spot stocks in our Tianjin warehouse. This enables us to promptly fulfill orders for seamless steel pipes, stainless steel pipes, carbon steel pipes, high-temperature alloys, European standard steel pipes, wear-resistant plates, medium and thick plates, high-strength steel plates, stainless steel plates, and high-pressure boiler plates.

With a global sales and service network spanning across all countries, we prioritize efficient and timely delivery to our customers. Our commitment to customer satisfaction extends to offering customized production and processing services, tailored to meet specific requirements.

Our products are exported to over 50 countries and regions worldwide. Guided by our core values of "quality first, customer first, integrity management, and win-win cooperation," we operate with a spirit of truth, pragmatism, change, and innovation. Our unwavering commitment to integrity and professionalism drives us to provide exceptional service to our valued customers.

|Our Services for SGCC Galvanized Steel Coils

Hot-dip galvanizing is really an interdiffusion reaction between molten metal and the iron base to produce an alloyed layer thereby uniting the base with the coating. Hot-dip galvanizing is to pickle iron and steel pieces first in order to remove the iron oxide that is present on the surface of the iron and steel pieces and that reappears after pickling; they are scoured in an aqueous solution of ammonium or zinc chloride or of a mixture of ammonium and zinc chloride.Then they are carried to the hot-dip plating bath.The main benefit of hot-dip galvanizing is that it provides uniformly coated products with strong adhesive strength and long service life.

Pre-Sales Service

Customized solutions tailored to your specific project requirements.

Efficient and accurate order processing for faster lead times.

Comprehensive technical support to address any product-related questions or concerns.

Transparent pricing and flexible payment options for a seamless purchasing experience.

After-Sales Service

Dedicated customer support channels for personalized assistance and prompt resolution of concerns.

Continuous improvement based on customer feedback, ensuring an enhanced product experience.

Regular updates on product enhancements, new features, or relevant industry developments.

|Other

Product

|

FAQ

Q1: May I visit your factory?

A: Certainly! We warmly welcome visitors to our factory.

Q2: Can you provide samples?

A: Yes, we can provide free samples. However, the buyer is responsible for the freight charges.

Q3: How long is your delivery time?

A: If the goods are in stock, the delivery time is generally 3-7 days. If there is no stock, it may take 7-15 days, depending on the quantity of the order.

Q4: How do you guarantee the quality of the goods?

A: We always provide a pre-production sample before mass production and conduct a final inspection before shipment to ensure the quality of the goods.

Q5: How can I get a quote?

A: To receive a quotation, please provide us with the specifications of the required products, such as material, size, shape, etc. This information will enable us to offer you the best quotation.

Q6: What is your packing method?

A: We offer export standard packaging or can accommodate specific packaging requests from customers.

|

Certifications