Phone / WhatsApp:

+86-13288385958

E-mail: sale20@shunbeifactory.com

E-mail: sale20@shunbeifactory.com

Xingye 9th Road, Guanglong Industrial Zone, Yongxing village, Chencun Town, Shunde District, Foshan City, Guangdong, China

Dx54d+Z

600mm to 1500mm

Z30~Z275g/m2

zero/small/regular/big

AiSi, ASTM, bs, DIN, GB, JIS

Roll

GI Steel

10 TON

Industrial

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

| Dx54d+Z steel coil is a premium quality carbon steel that is galvanized after being enhanced by technology hot-dip galvanizing. Such a process builds up a protective zinc layer of the finest quality closely adhering to the surface of the steel tremendously upping the steel’s resistance to corrosion. It possesses very favorable mechanical properties, featuring high tensile strength (260-350 MPa) and optimized yield strength (120-220 MPa),characteristics that are well suited for deep drawing applications in both automotive and construction indus | |||||||||

Product Description

|

PRODUCT DESCRIPTION

Dx54D+Z is a deep drawing grade hot dip galvanized steel in accordance with EN 10346 with excellent formability and good corrosion resistance. This steel grade is mainly used in the automotive, home appliance and construction fields, especially for the production of complex stamping or stretch forming parts.

|

SURFACE STRUCTURE

Zinc layer

Cold-Rolled Steel

Zn Coating Layer

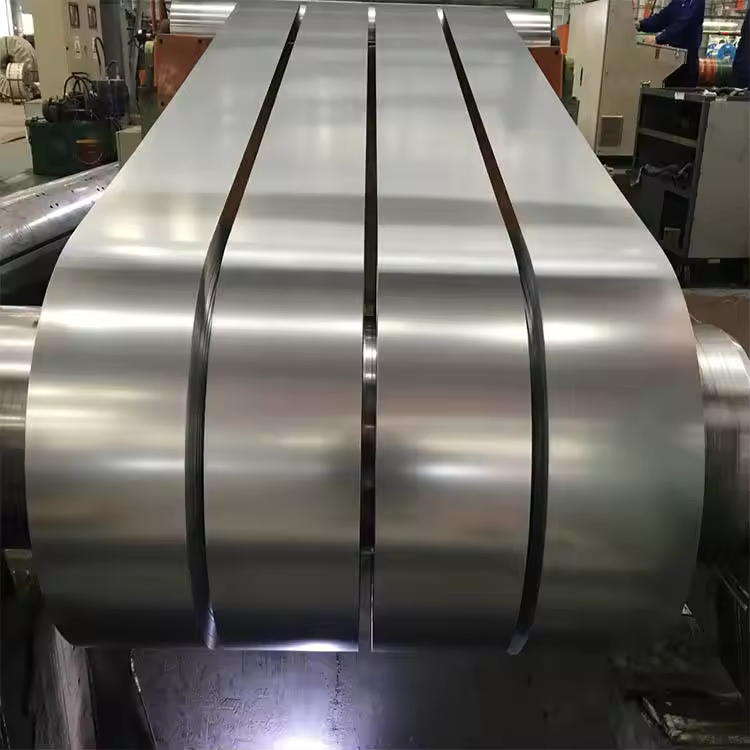

DX54D+Z galvanized steel coils

Dx54D+Z galvanized steel coil adopts hot dip galvanizing process to form a uniform zinc layer on the surface of the steel substrate, providing excellent corrosion protection. Its "D" series stands for deep drawing performance and is suitable for higher deformation processes. The surface can be provided in various forms such as skin passed, passivated, oiled, dried or chemically treated according to customer needs.

|THE SURFACE OF GALVANIZED STEEL COILS CAN BE DIVIDED INTO FOUR TYPES

No Spangle:The galvanized steel coil’s surface with no pattern is indistinct zinc grains while the entire surface has a smooth appearance.

Small Spangle:The surface of the small-pattern galvanized steel coil is fine zinc grains with a fine pattern.

Regular Spangle:The surface of the galvanized steel coil displays medium-sized zinc grains in a regular pattern.

Big Spangle:It exhibits a larger pattern since it has larger zinc grains on the surface of the galvanized steel coil.

Product Specification

| Item | Parameter Range |

| Thickness | 0.25 – 3.0 mm |

| Width | 600 – 1500 mm |

| Roll Weight | 3 – 10 tons |

| Zinc Layer Weight | Z80 – Z275 (g/m²) |

| Surface Treatment | Smooth/Unsmooth, Passivation/Passivation + Oiling, Chrome-free Passivation |

| Edge Treatment | Cutting/Burning |

| Standards | EN 10346, DIN 17162, ASTM A653 (optional) |

|

APPLICATION

Automotive Industry: Body Inner Panels, Reinforcement Ribs, Chassis Components

Home Appliance Manufacturing: Refrigerator Back Panels, Washing Machine Shells, Air Conditioning Components

Construction Engineering: Roof Panels, Wall Systems, Air Ducts, Door and Window Structures

Electrical Boxes: Control Cabinets, Electric Meter Boxes, Distribution Boxes, etc.

Furniture Industry: File Cabinets, Shelves, Metal Cabinets, etc.

MECHANICAL PROPERTIES

Performance Item Value (Typical Value)

Yield Strength (Rp0.2) ≤ 140 MPa

Tensile strength (Rm) 270 – 380 MPa

Elongation A80 ≥ 38%

Bending performance 180° crack-free bending (T≤2mm)

Product Image

|

PRODUCT DISPLAY

Product Process

|

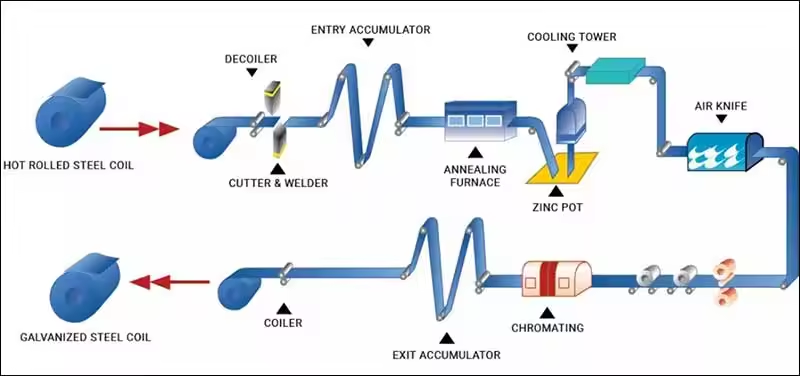

PRODUCT PROCESS

Raw material selection: low carbon cold rolled steel coil as base material

Cleaning and annealing: improve surface and formability through pickling and annealing

Hot dip galvanizing: the steel coil passes through the molten zinc pot to achieve zinc coating

Air knife zinc control: the air knife controls the uniform thickness of the zinc layer

Surface treatment: passivation, oiling or chemical passivation treatment

Coiling and packaging: customized weight, marking and packaging according to customer requirements

|

Product Packaging